Permanent Mold Castings

Front Cover

This 37-lb. front cover for a light truck application was designed with the permanent mold process in mind. It measures 20 x 28 x 6 in. and was required to meet strict pressure tightness parameters. The cast component features six separated cored passages and chambers for oil and coolant, along with integral water pump geometry. Walls in some areas are as thin as 0.18 in.

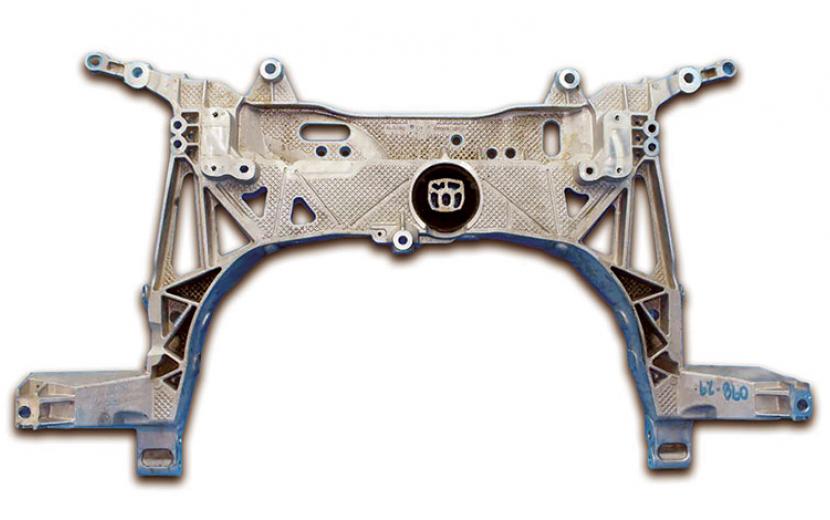

Front Chassis

A front chassis and suspension component for an electric vehicle, this casting takes advantage of the fluidity of A356 alloy. By using creative gating design, the supplier was able to make the casting with uniform wall thickness and meet the internal, subsurface and surface soundness requirements, which were validated by rigorous nondestructive testing. The thin and uniform wall thickness is helpful in optimizing weight, and low pressure permanent mold casting is a near net shaped process that provided excellent surface finish and dimensional tolerances. Permanent mold allows directional solidification using heating and cooling channels placed strategically into the mold cavity.

Intake Manifold

The aluminum construction of this aftermarket manifold is ideal for nitrous, supercharged and turbo applications. The Victor II features cast bosses on the runners for a direct port nitrous system for competition applications. The low-profile design fits all factory 2011-2016 Ford Mustang hoods and strut tower braces. The manifold features long tapered, crossover-style runners with a large plenum for outstanding performance.

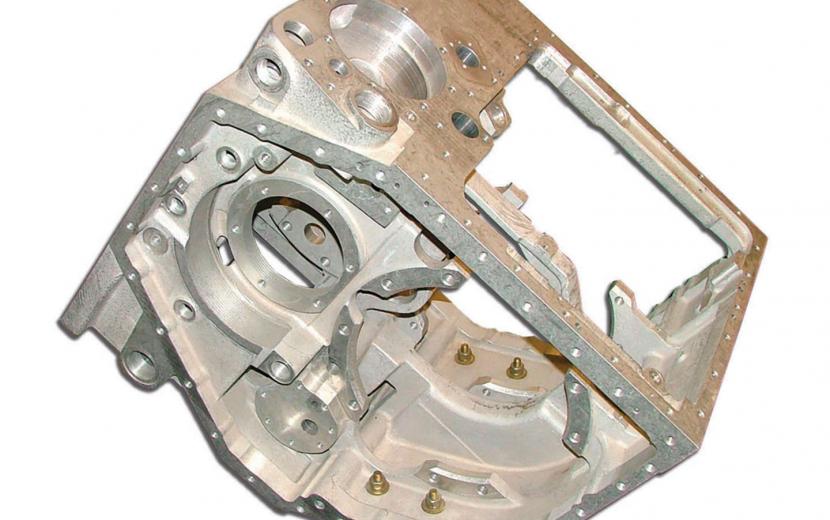

Transmission Main Housing

This alumninum transmission main housing was cast via semi-permanent mold using 27 sand cores.

Snowmobile Component

This lightweight aluminum casting features 4-mm walls and 29 windows. It was produced via low-pressure permanent mold casting.

Known for its ability to achieve tight tolerances, superior surface finishes and high mechanical properties, permanent mold is a quality option for many applications.

Click here to read more about the basics of permanent mold.

Want to read more articles like this? Subscribe here.