Diecasting Examples

Magnesium Lift Gate

The magnesium lift gate for the 2017 Chrysler Pacifica represents one of the first major entries into high-volume magnesium diecasting for the automotive industry. Produced by Meridian Lightweight Technologies, it replaced a seven-piece steel weldment and reduced the amount of joining technologies, such as spot welds and rivets, from 84 to 10.

Fan Bracket

Big Ass Fans (BAF) in Lexington, Kentucky, purchases diecast components for its massive ceiling fans you will find at stadiums, warehouse stores and gyms. Most of the castings purchased by BAF are diecast aluminum, but some pieces with thin walls or that require chrome plating, like the switchplate here, are diecast in zinc. BAF assembles its fans in Lexington and sources a large majority of its components in North America.

Side Door Mirror

The light-duty side door mirror reinforcement bracket produced by Magna Cosma Casting Michigan is a single piece, vacuum diecast aluminum Aural 5S alloy F (as-cast) temper casting. The aluminum casting provided engineers with more design flexibility and more efficient attachment points. This casting replaces a traditional five-piece aluminum stamped and welded assembly with a mass savings of 20% (37% mass savings over a steel design) while improving the stiffness at the weak point of the side door window frame.

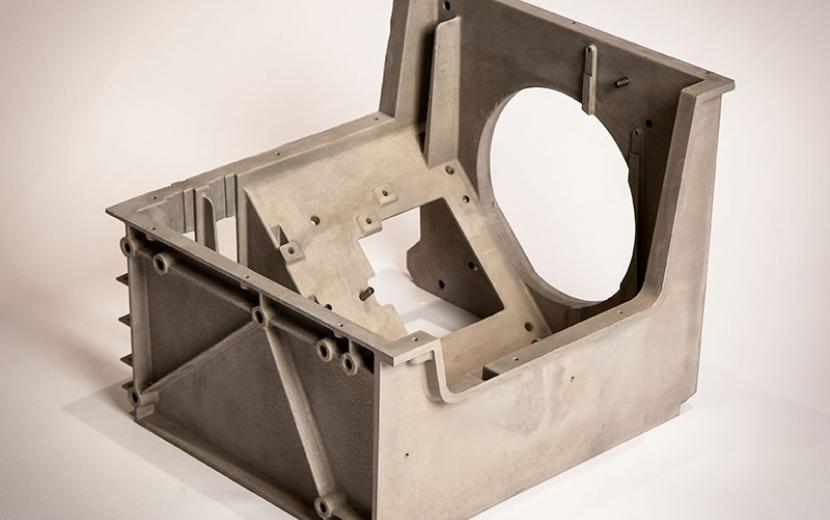

Projector Housing

This diecast housing is for a projector.

Is one of the most common casting methods a good choice for your part?

Click here to read the story.